Weed management in sugarcane under wide-row planting

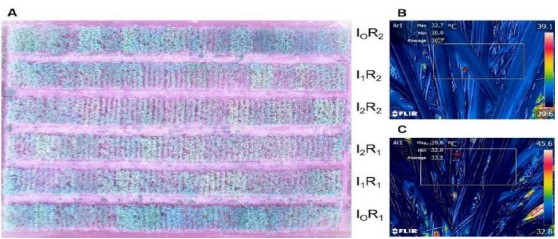

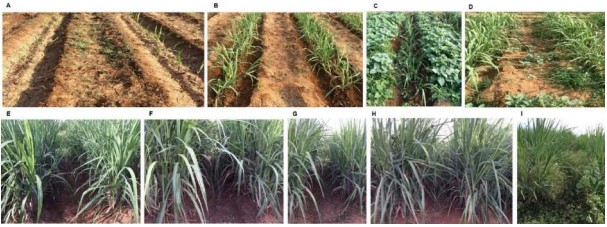

♣ Severe weed infestation in widely spaced sugarcane plant crop can be effectively managed in an integrated manner by sequential application of early post-emergence application of metribuzin at 1250 g a.i. ha-1 at 10 DAP followed by post-emergence tank mix application of either topramezone at 29.4 g a.i. ha-1 + atrazine 625 g a.i. ha-1 or tembotrione at 120 g a.i. ha-1 + atrazine 625 g a.i. ha-1 or halosulfuron methyl 67.5 g a.i. ha-1 + metribuzin 525 g a.i. ha-1 at 65 DAP followed by one hand weeding at 120 DAP. This has proved to be cost-effective in widely spaced sugarcane plant crops with higher weed control efficiency, weed control index, broad spectrum weed control, and no phytotoxic effect, in turn improving cane growth and yield.

Photo (A)Field view of sugarcane variety Co 86032 at 15 days after planting (DAP), (B) Effect of early post-emergence application of metribuzin at 45 DAP (at the time of partial earthing up) (C) T8 (unweeded control) at 45 DAP, (D) Weed infestation before application of herbicides at 65 DAP, (E) T1 (Topramezone + atrazine) + hand weeding at 160 DAP, (F) T3 (Tembotrione + atrazine) + hand weeding at 160 DAP, (G) T5 (Halosulfuron methyl + metribuzin) + hand weeding at 160 DAP, (H): T7 Three hand weeding at 160 DAP, (I) Unweeded control at 160 DAP A simple and sensitive chromatographic method has been developed and validated to determine the residues of halosulfuron-methyl in the soil matrix. The method developed is in compliance with European Commission’s regulations for Trace Residue Analysis. By adopting this method, the persistence and dissipation kinetics of halosulfuron-methyl was studied. The initial deposits of halosulfuron-methyl were 0.288 and 0.501 µgg-1 at the recommended dose (RD) and double the recommended dose (2RD), respectively. A week after application (7 DAA), the residues were 0.177 and 0.346 µgg-1 , respectively for RD and 2RD. The residues got dissipated to a level of about 95% within 75 days of application with the half-life of 9.12 and 9.71 days.

♣ A simple and sensitive chromatographic method has been developed and validated to determine the residues of halosulfuron-methyl in the soil matrix. The method developed is in compliance with European Commission’s regulations for Trace Residue Analysis. By adopting this method, the persistence and dissipation kinetics of halosulfuron-methyl was studied. The initial deposits of halosulfuron-methyl were 0.288 and 0.501 µgg-1 at the recommended dose (RD) and double the recommended dose (2RD), respectively. A week after application (7 DAA), the residues were 0.177 and 0.346 µgg-1 , respectively for RD and 2RD. The residues got dissipated to a level of about 95% within 75 days of application with the half-life of 9.12 and 9.71 days