SETT-TREATMENT DEVICE

An effective way to deliver agro-inputs for planting materials of sugarcane

Introduction

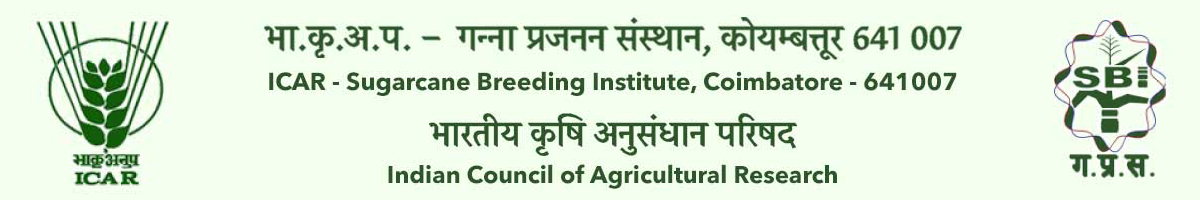

It is well known that the sugarcane planting material serves as primary source for most of the diseases caused by fungal (red rot, smut, wilt), bacterial (ratoon stunting, leaf scald), viral (mosaic, yellow leaf disease) and phytoplasma (Grassy shoot disease) pathogens. The non-fungal diseases can be inactivated or eliminated through heat treatment or tissue (meristem) culture techniques. However, the fungal pathogens have to be tackled through effective sett treatment with fungicides/ microbes/ other molecules. Our earlier experiments revealed that the effective diffusion of fungicides inside the setts require prolonged duration (overnight) of soaking. Since it is cumbersome to handle huge volume of seed canes for fungicide treatment, ICAR-SBI has developed a technology with prototype (The Patent Office Journal 21/06/2013) to deliver fungicides or beneficial microbes effectively and rapidly in the setts. Based on that technology, the Institute has fabricated bigger sized sett treatment units in collaboration with ICAR-CIAE under DST-IDP project to treat setts with fungicides and other agro inputs for disease management and healthy nursery programme for large scale application. Field trials conducted at the Institute and sugar factories established that effective fungicide delivery through the device has significantly reduced red rot, smut and wilt development from sett and soil borne inocula for 3-4 months in the field. Further in healthy nursery programme, effective treatment of single bud setts with fungicide, insecticide, macro and nutrients benefitted in producing vigorous settlings. This method of sett treatment is an improved method over conventional sett soaking and has several benefits.

Technical Description

Sugarcane stalks at proper physiological conditions (8-10 months old) suitable for planting were selected, cut at the bottom and dried leaves and green tops were removed. From the selected canes, the suitable stalk portion with active buds, leaving the top and bottom portion of the stalks having immatured or over matured buds was used for making setts. The stalks were cut into single bud setts with cleaned knife and selected the setts with good buds leaving the damaged ones. Here the setts of single/ double/ triple budded and bud chips were tried. The setts were taken in the container having lid with connector provision for connecting tube. The suspension to be treated with the setts was prepared and added to the container till the setts were immersed in the solution. The solution can be of any agrochemicals viz., fungicide/ insecticide/ growth regulator/ adhesives/ nutrients or microbials prepared in water. The container was closed airtight with its lid and the outlet from the lid was connected to the vacuum pump. Then the vacuum was applied slowly @ 100 to 300 mmHg for 15 to 20 min. depending on the size of the machine, setts and combination of agro-inputs. Under vacuum, it removes air in the container and setts i.e. it creates negative pressure and then the vacuum was released slowly for 5-10 minutes which led to absorption of surrounding solution inside the tissueThe absorption was confirmed by tissue bioassay in the decreasing order of buds, rind, cut ends, nodal and internodal stalk tissue. Also the absorption was found to be equal as overnight soaking. Then the same solution was repeatedly used for treating the next batches of setts on the same day and confirmed similar effect.

Salient Features

Invention relates to new technique for the treatment of sugarcane planting material (single/ double/ triple budded setts/ bud chips) with any agrochemicals or microbes for protection from diseases/ pests and improvement of plant growth. This novel technique has principle of creating negative pressure followed by absorption. This method of sett treatment is an improved method over conventional application as sett soaking at different periods of time. This method of mechanized short-term treatment has advantages viz., rapidity, effectiveness, less cumbersome in handling material, capable of delivering more than one agrochemical/ microbes/ endophytes, uniform treatment with evenly dispersed chemical, economical as it consumes less chemical and suitability for large scale application under farmer’s field condition. Besides above all, it is possible to adopt this technology for treating planting materials of other vegetatively propagated field and horticultural crops viz. tubers, stem cuttings, corms etc.

Commeralization

From the institute and factory trials conducted for more than 10 years with the prototype and with the newly fabricated units of Sett Treatment Device (STD) for 5 years, it was confirmed that this Device is highly effective in treating sugarcane planting materials for fungal disease management and healthy nursery programme. Such a multi-use device technology has been commercialized during KISAN MELA-2016 of ICAR-SBI on 26-08-2016 by Dr. K. Ramasamy, Vice-Chancellor of Tamil Nadu Agricultural University and licensed to an entrepreneur (M/s.CLEANTEK, SF. No. 479/4, Site No. 22 & 23, Balaji Industrial Esae, Kondayampalayam Main Road, Keeranatham, Saravanampatty (P.O), Coimbatore – 641035, Tamil Nadu) to mass produce the device for large scale application in different states. Till now, this firm has supplied about 75 units to factories and private entrepreneurs throughout India.

Demostration of Sett-Treatment Device at Various Sugar Factories

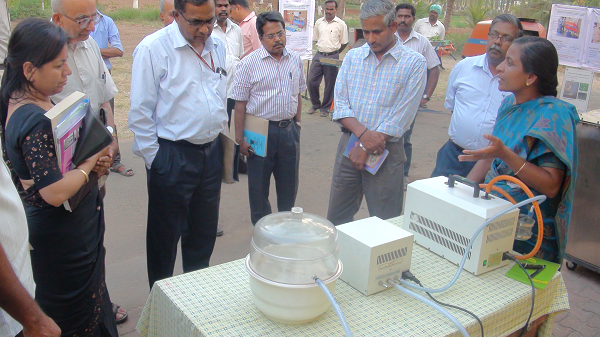

Demonstration of Prototype in front of DST-IDP committee for fabricating bigger units at CIAE, Coimbatore (2013)

Validation of second fabricated unit for red rot and smut diseases management under field conditions, Shri Ambika’s Sugars, Tuhili, Kumbakonam (2014-15)

Publications

♦ Article in International journal-2017

♦ ICAR annual reports and NEWS

♦ Press-popular

♦ Recent report in international conference-2018

♦ SBI NEWS – 2015-Efficacy of STD

♦ STAI proceedings- field application – 2016

♦ SBI-NEWS – 2017- Package for STD

♦ STD-recommended technology among 101 technologies of TN

Contact Us

The companies / firms interested to take Sugarcane Sett Treatment Device technology must Email to:

The Director

ICAR-Sugarcane Breeding Institute,

Coimbatore – 641 007.

E-mail: E-mail: director.sbi@icar.gov.in;abi.sbi@icar.gov.in;itmu.sbi@icar.gov.in

Off: 0422 – 2472621 (Ext: 203), 0422-2473971

Contact Address

-

ICAR-Sugarcane Breeding Institute

Veerakeralam,

Coimbatore 641007

Tamil Nadu. - Phone: 0422 - 2472621

- Email: director.sbi@icar.gov.in

- GST Number 33AAAAD2962K2ZT

Our Visitor Count